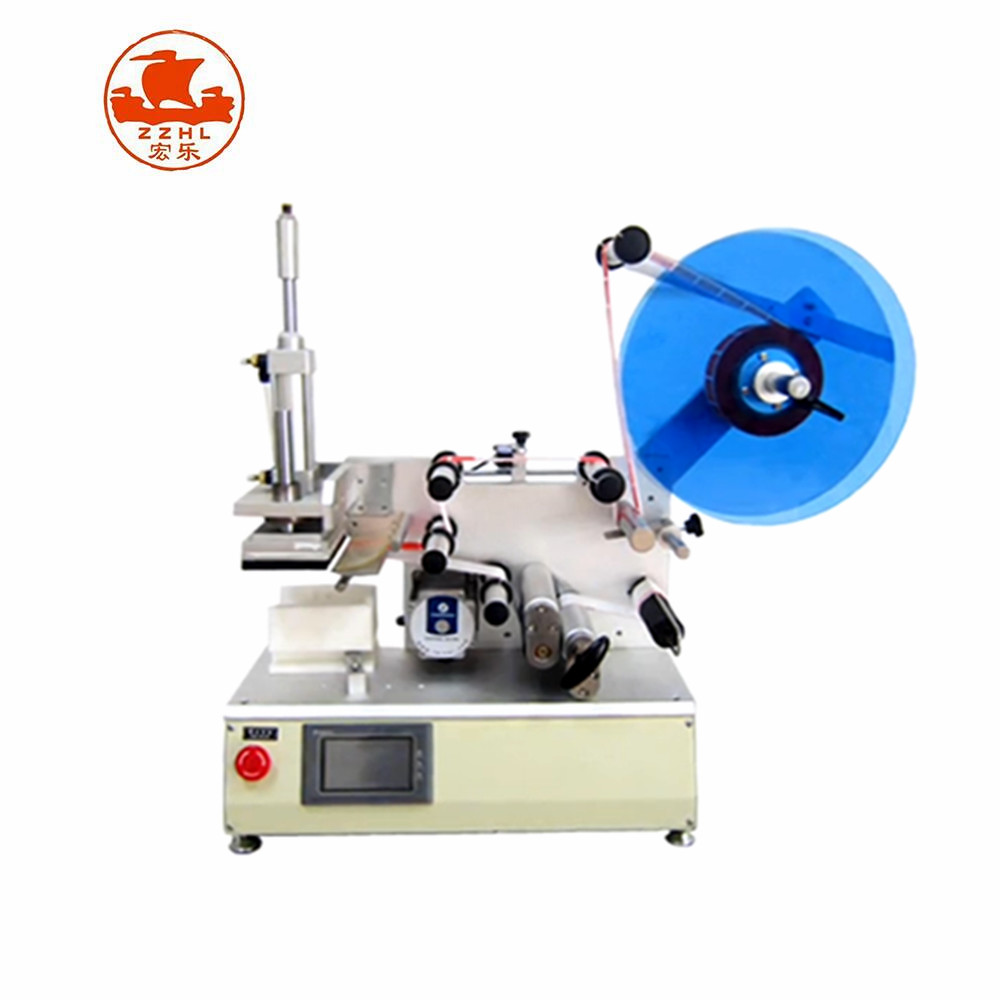

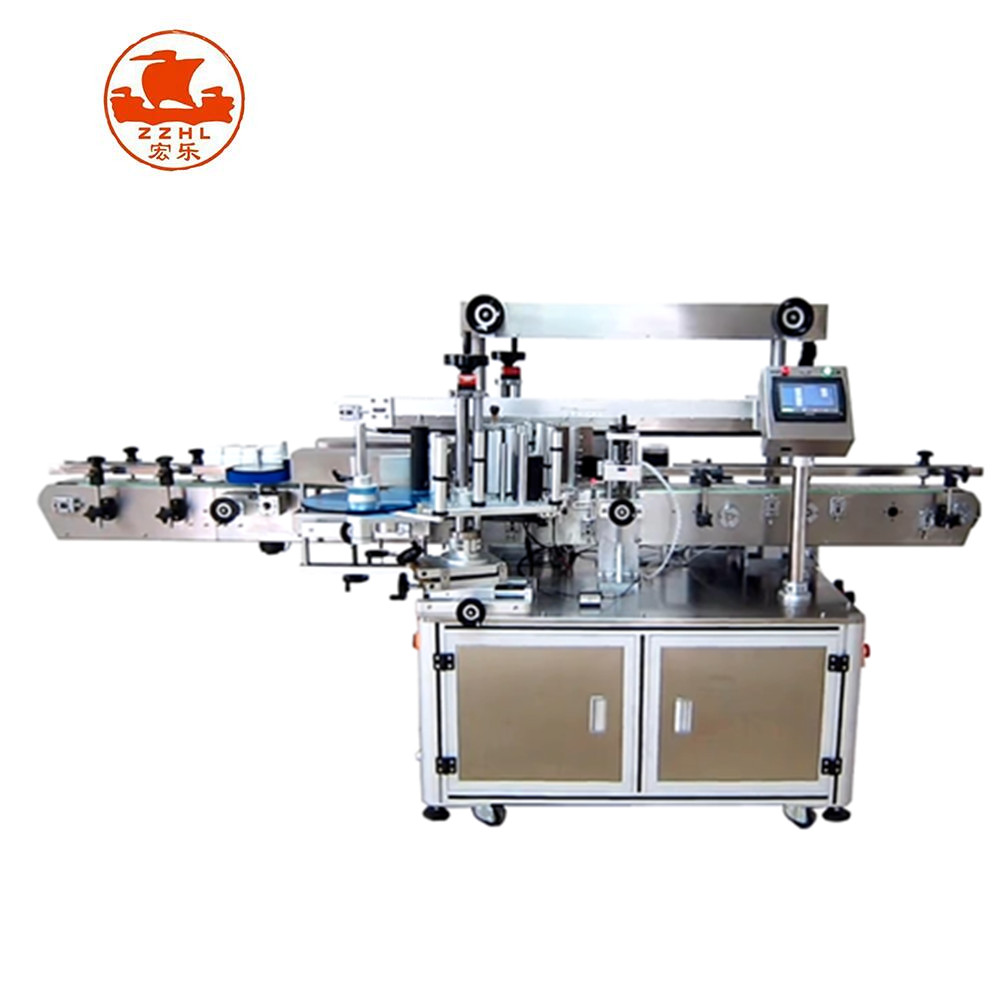

Square bottle label machine

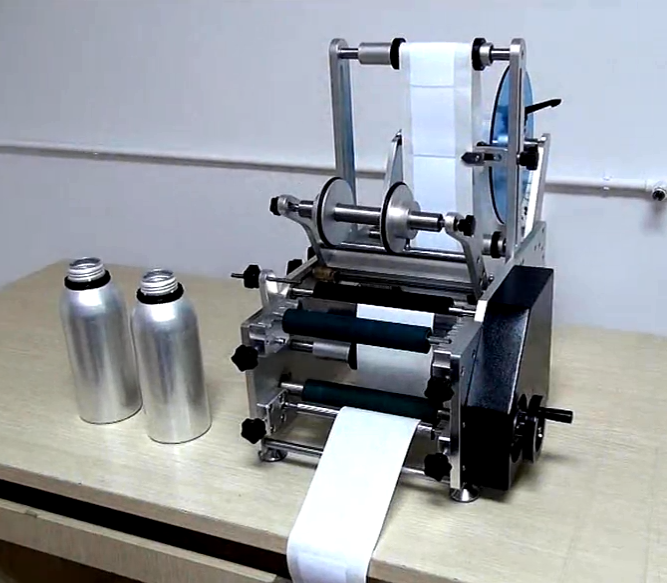

1.It’s belong in semi labeling machine, adopt inhaling label and then stick for all kinds of plane surface of product. Like flat bottle of cosmetic, packing box,plastic cover etc.

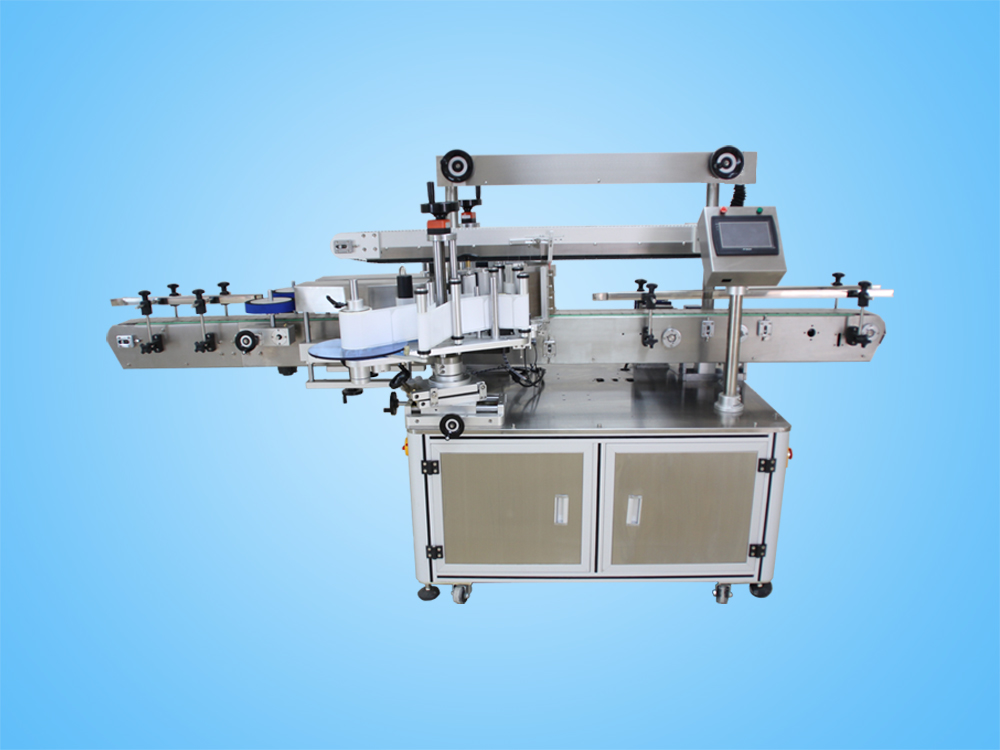

2.To change the label cover mechanism , labeling can be finished on uneven surface, like concave surface,curved surface and so on.

3.To change relevant management tool, labeling can be operated on not regular shape’s product.

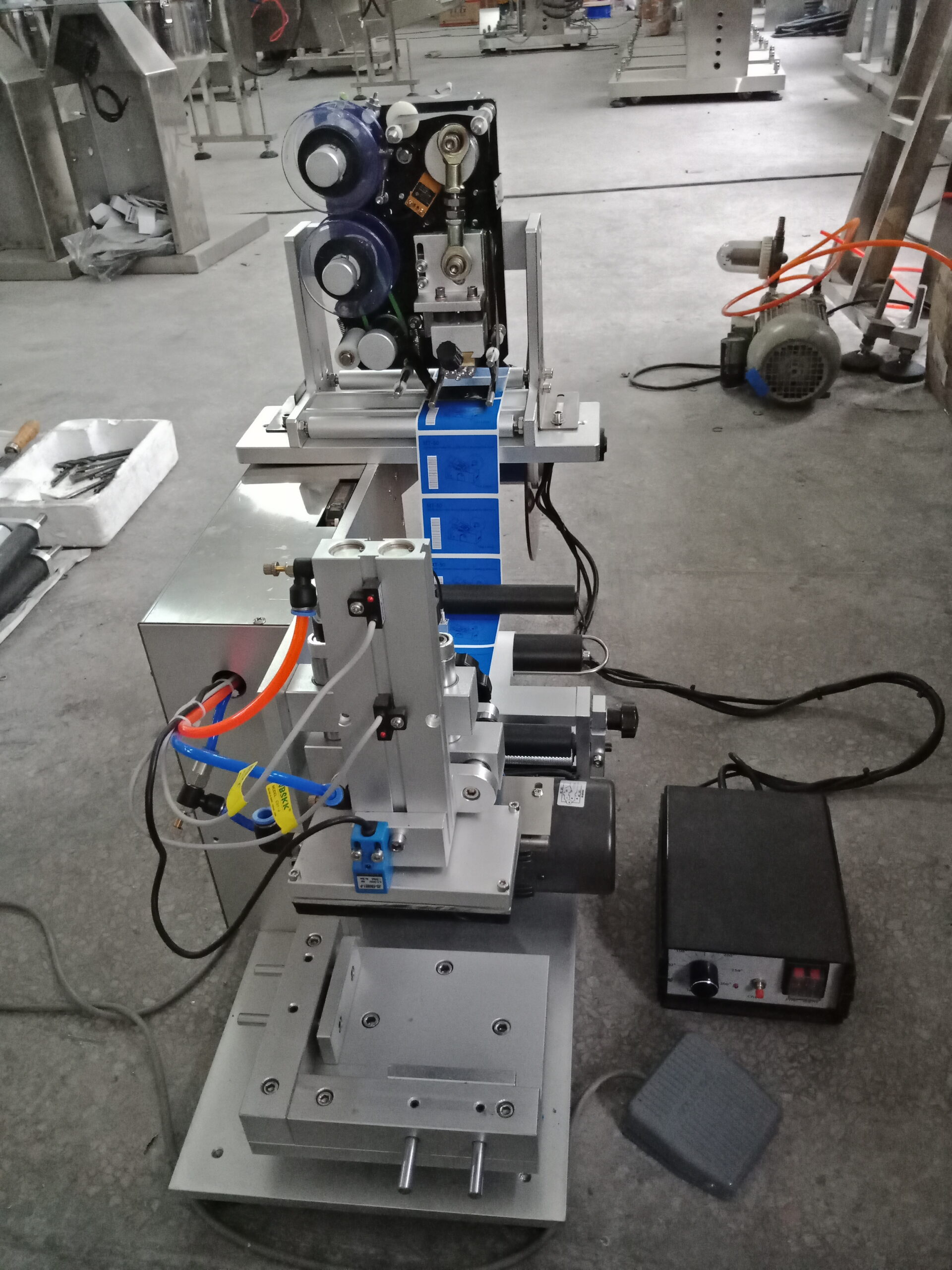

4.Select match color ribbon printer or inkjet printer to print product date and system’s number on label, let integration of printing – labeling become true.

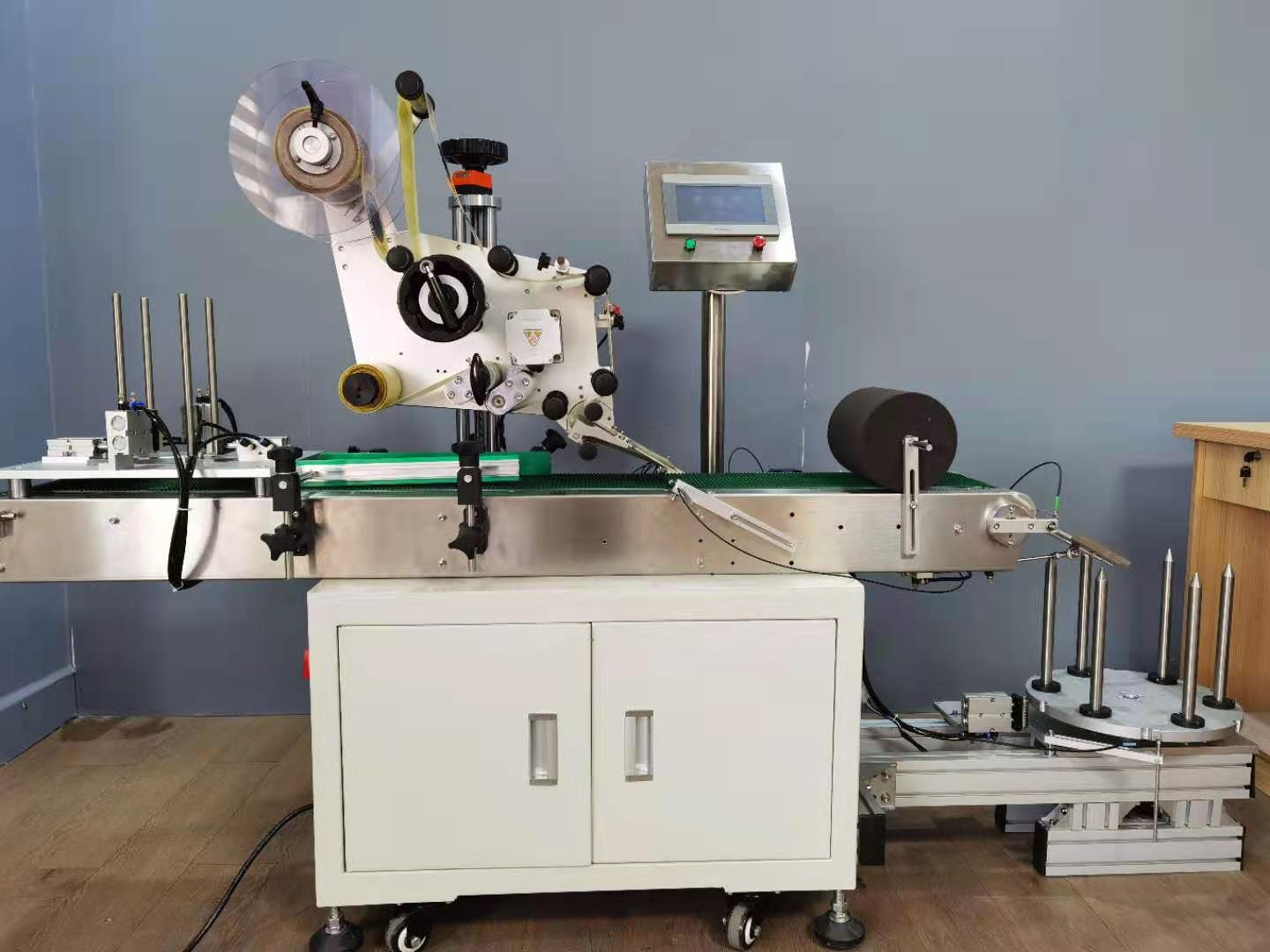

5.Can be sued match with various assembly line.

1.Function strong, can be used on every plane, circular, concave surface to label,can be operated on not regular shape’s product

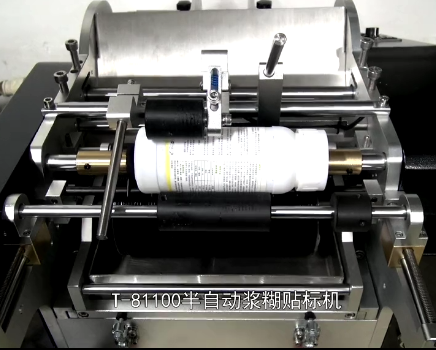

2.Labeling accurate, high stability, adopt PLS + Stepper motor driver to conveyor labels, more accurate; mechanism for material with brake function to sure label belt is tight, and sure label testing accurate; label road have check and correct mechanism to avoid label run to right or left.

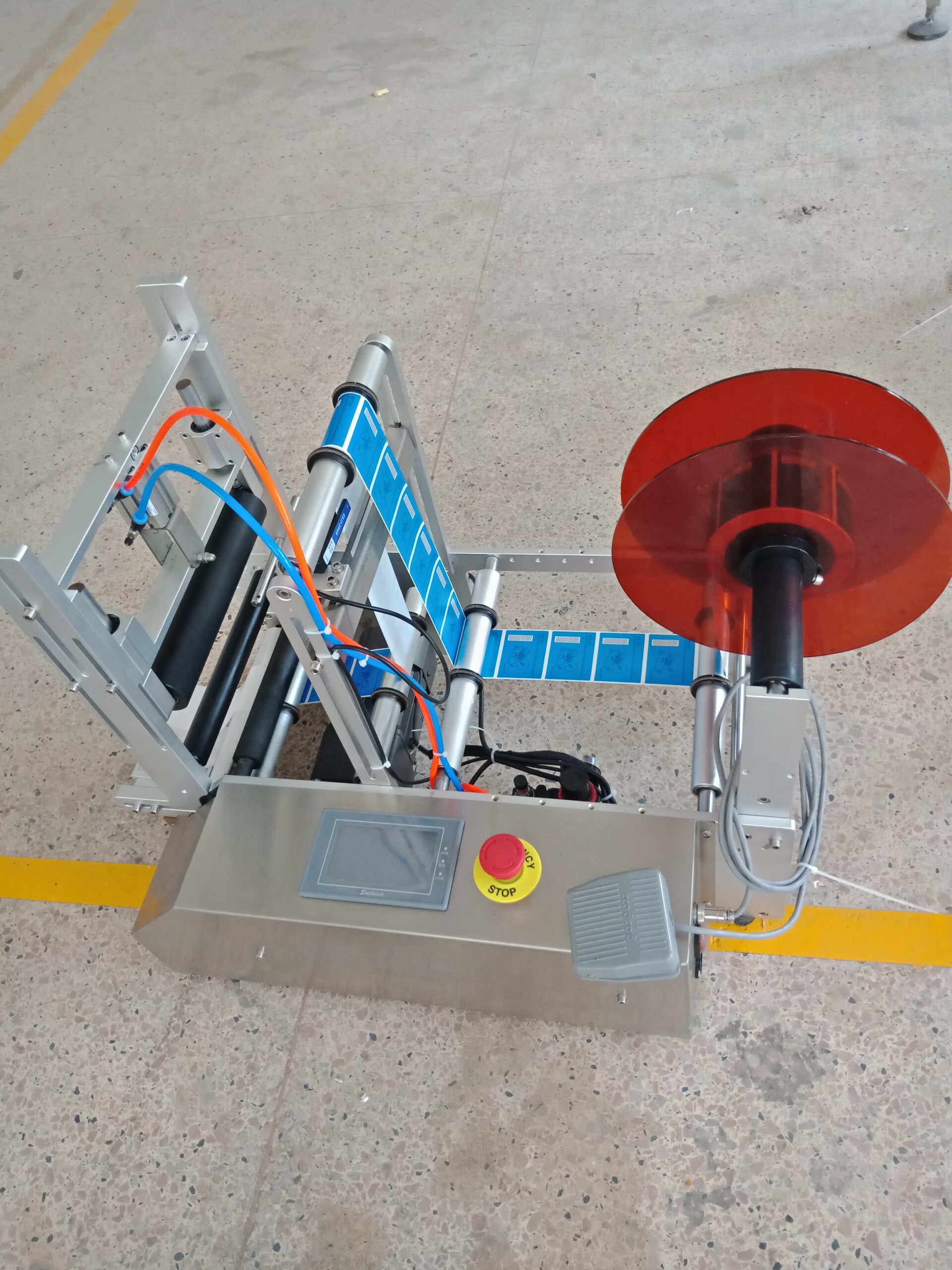

3.long life and Durability, electric road apart with air road, setting up decontamination plant on air road avoid drop into electric equipment, to expanding product’s life. Whole equipment under high grade stainless steel and aluminum alloy, it’s strong.

4.Adjustment convenient, have function of adjustable stroke, no need to change the relevant management tool for different height of product.

5.Attractive looking, adopt computer electric box set up bottom, match material of stainless steel and aluminium ally to improve product’ grade.

6.Having manual/automatic 2 method to control labeling, worker can select to use sensor or food stepping the control labeling when they face to different circumference.

7.There are accordingly button of manual or automatic controller, and label length could be debugging as per requirement.